Gary Dobyns tests Dobyns Rod for durability.

Gary Dobyns is one of the most successful tournament anglers in the west. He has won major tournaments on just about every major body of water, but he may now be best known for Dobyns Rods. Just wrapping up their tenth year of business, Gary has become an expert on what makes a good rod and the importance of each component.

Rod Blanks

The quality and type of rod blank used is essential for producing a quality rod. Dobyns calls it the “heart of the rod” and with good reason. “If the blank is not good, it won’t matter what components you put on it,” he explained.

Dobyns Rods are all built on the spline and from a high-grade material; Korean SK and Japanese Toray carbon. This makes a different according to Dobyns as there are less flaws and defects.

Rod Guides

There are many different sizes and types of rod guides and Dobyns feels that having a quality guide is essential. “The biggest problem rod makers have is guide failure,” he said. “The inserts come out, it is a bigger issue than rods breaking.”

He talks from experience of seeing rods being returned and uses both Fuji and Sea Guide guides on all of the rods his brand produces as a way to reduce damaged rods.

“I’m a big fan of tangle-free guides; because many anglers use braid and other guides can cause braided line to wrap around the rod,” he said.

Dobyns prefers guides with stainless steel frames and inserts made of alconite, SIC or zirconium.

“Stainless steel prevents corrosion or rust,” he explained. “Rust will get under the wrapping of the guides and cause problems later. We avoid this altogether with a stainless steel frame.”

Reel Seats

The reel seat is a vital part of the rod and can instantly ruin a rod, if it fails.

Dobyns and many other rod companies use Fuji reel seats. “They are always consistent," he said. "Fuji never has issues and that is why we use them on every rod we make."

Rod Handles

One of the major trends in rod handles is the use of EVA or Hypalon; but for the most part, Dobyns sticks with cork handles.

“We only use high-end cork," said Dobyns. "We never use less than AA-Grade Portugal cork and only AAA-Grade on the Champion Extreme Series."

Trim and Winding Checks

The trim pieces on a rod serve a decorative purpose, but also help with durability. “Some rods are built with rubber winding checks and once they start to fail, they just come apart,” he added. “That is one of the reasons we use all aluminum winding checks.”

Hook Keepers

The hook keeper is one of the smallest pieces on a rod, yet often the most important for picky anglers.

“We built a custom hook keeper on all of our spinning rods that will hold a dropshot weight better than any others I have seen,” said Dobyns.

Rod Action

Dobyns Rods has 160 different models and each of them have a custom action.

“We vary them and build them for specific purposes,” he said. “Some are fast, some are what I call a ‘fast-plus’ and some are much slower in action.”

Fast-plus is an in-house term coined by Dobyns to describe a very fast rod that he prefers. In the Dobyns Rods line, it is a rod action that lies between fast and extra-fast.

The Sierra Series has a slightly slower action than the Champion Series. "There is a large group of anglers that do not prefer a really fast rod," explained Dobyns. "Even though the Sierra still rates out 'fast', it is slightly slower, which is something that many smallmouth fishermen like, because of how much they jump."

Having a variety of rod actions, like those that are included in the many Dobyns Rods products will further your ability to use a technique specific rod.

Rod Balance and Weight

Rod Balance and Weight

“Balance makes a rod more sensitive,” said Dobyns. “If a rod is light in the tip, the entire feel will be better.”

Weight and balance go hand in hand and rod builders like Dobyns pay close attention to weight. They build blanks with balance in mind.

“When thinking of rod balance, there are several strategies that we implement," said Dobyns. "We reduce guide size, when possible. We also use less paint and guide epoxy to keep the weight down. Balance is a huge deal.”

Fishing Rod Testing and Breakage

Fishing rods can and will break. Thankfully, some companies - like Dobyns Rods - do everything to make sure they find issues before the rod is purchased by the consumer.

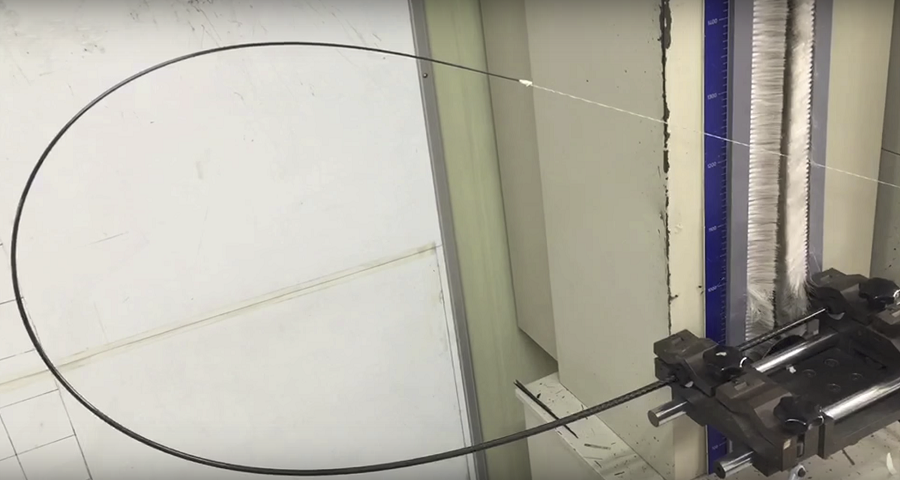

Dobyns explained some of the ways that his rods are tested, which included a deadlift test, a high-stick test and a repetitive hookset test - repeated for 2000 hooksets. Machine testing is one thing, but not where the quality assurance ends for Dobyns Rods. Before a rod goes into production, Gary himself does everything he can to see if he can break a rod. It is the "torture test".

“People just laugh when they see me on the water,” recalled Dobyns. “I high-stick the rod, cast with two 8” swimbaits on the same rod and anything else I can do to try to break one. I do everything that you are not supposed to do. This ensures that the blanks are tested thoroughly before they are even produced."

The other rod quality tests are more systematic. The deadlift test is done twice through building process. Once the blank is completed, its deadlift tested and again right after assembly, before packaging. "The breakage rate is very low but insures a customer is far less likely to get a defective blank from us," explained Dobyns. "This deadlift test is not a random test. We do it for every single rod. It is done with a machine; so the test is the same every single time.”

Gary Dobyns is committed to building a quality rod and has learned the importance of having the right components. Each piece that he and other top rod builders use are essential in making the perfect rod.

Advertising

Advertising