There are countless articles, tips, and videos out there for maintaining your outboard engines, but when it comes to your trolling motor, there is less information available.

There are countless articles, tips, and videos out there for maintaining your outboard engines, but when it comes to your trolling motor, there is less information available.

Maintaining your trolling motor can lead it to a longer life and keep you on the water longer.

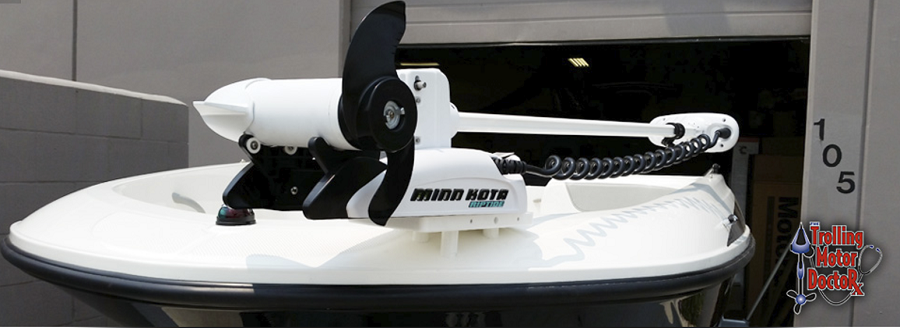

Nick Wayne of the Trolling Motor Doctor repairs motors every day and offers the eight tips to keep your MotorGuide and Minn Kota motors running perfectly.

#1 Line and Grass Under Trolling Motor Prop

#1 Line and Grass Under Trolling Motor Prop

While this is a common problem, many people still do not check behind the trolling motor prop for fishing line and grass.

“We see this often when someone comes in and says their motor isn’t working right. It is easy to check and fix yourself,” says Nick. The problem can get costly if the line is wrapped deep and damages the seals. Nick recommends removing the prop nut and checking for line and grass every few trips.

#2 Lube and Grease Metal Parts

Each brand and model of trolling motors are a little different, but Nick says one thing he recommends is to grease any metal parts that come in contact with other metal.

“The locking pins on the mount should be greased so they move easier. This also prevents wear and saves your pull rope,” he adds.

If you run a motor with electric steering like the Minn Kota PowerDrive, Terrova or MotorGuide Xi5, Nick says to grease the locking pin and pivot pin and also clean the shaft.

“Cleaning the shaft or using Armor All helps it work much better,” he said.

#3 Electrical Connections

The plug that connects the trolling motor to power is typically located right up front of the boat and this can lead to damage over time.

“This is a place where water is going to splash and that can lead to corrosion. It may happen slowly, but it will require more amps to run the motor,” he says. “Some people run out and buy new batteries and then have the same problem.” He says to check the plug often and clean any connections.

Batteries are another key to keeping your trolling motor running. “I always make sure every connection is tight,” he says. AGM batteries are what he prefers and adds that they help keep a trolling motor going longer. “They are a little more costly up front, but since they are sealed there is no corrosion from acid and gas. They give you a longer life and last longer while you are on the water.”

#4 Trolling Motor Props and Pulls

Like your outboard prop, a small ding in a prop can affect the performance of a trolling motor.

“I always check and if it is small a file may work to get it running better. If it is too banged up, you will just need to replace and having a back up with you is essential on the water,” he says.

He went on to say that the metal props that are available from MotorGuide (recommended only for 36V motors) are great for preventing damage to the prop while fishing shallow water.

The market for trolling motor pull ropes was developed after years of bass anglers breaking the stock ropes used by trolling motor manufacturers. The new versions are more expensive, but made of steel and built to last. Nick is a believer.

“The steel ones hold up and are more reliable, but just by lubing the pins and locking pins on your bracket you can really make the regular rope last longer because it is much easier to lift the motor,” he says.

#6 Rough Water Prep

Running a boat in rough water can lead to poundings on your boat and your back and your trolling motor is right up for all of the action.

“A strap, Bounce Buster or RAM Mount Stabilizer will keep your trolling motor secure and are definitely worthwhile to keep them protected,” he begins. “The problem is the magnets used in the trolling motor are very hard but also very brittle and break easily. A small chip loose from the magnet can cause the motor to grind and losing the whole magnet will keep the motor from working at all.”

#7 Saltwater Danger

If you take your boat in saltwater or fish brackish water, Nick explained a corrosion inhibitor is needed for any exposed metal. “Salt water always wins. I recommend the CRC Heavy-Duty Corrosion Inhibitor,” he says.

#8 Checking Your Brackets

Like the bolts on your outboard, the mounting brackets on your trolling motor should be checked to see if they are loose.

“Any bouncing around will affect the noise of the trolling motor. The motors mounted with nyloc nuts and washers are pretty much maintenance free, but the ones with rubber mounting need to be checked,” he says.

The Trolling Motor Doctor has been in business since 1989 and has been owned by Nick and Ann Wayne since 2003. They are located in Lakewood, CA and offer a wide selection of parts, accessories as well as repairs and sales for Minn Kota, MotorGuide and Torqeedo motors and Lowrance and Humminbird fishfinders.

Advertising

Advertising