difficulty on a 1 - 5 scale with 1 being uber easy and 5 being rocket science:

1

time required:

about 5 minutes

tools:

rag or paper towels

3/16 allen wrench

small cotter pin, or jewelers screwdriver, or something small and thin (no jokes about gators junk please...)

grease - marine grade bearing grease would be best but anything will do, it's most important that there is some sort of grease in there vs the bearing being dry

STEP 1: loosen the collar

using the 3/16 allen wrench loosen (but do not remove) the 2 allen head bolts enough so that the collar will easily slide down. you can tell that my bearing is dry by all the brown/orange rust in the area.

STEP 2: pull back the dust cap

I opened up a small cotter pin here to get inside the collar and carefully pull the dust cap back to expose the bearing. you can lift/move the shaft on the motor to relieve the side-to-side pressure on the dust cap.

STEP 3: pull back the bearing

I should have put the rag under the shaft to help catch anything that may have fallen out. but its the same thing here, used the cotter pin as well and rocked the shaft gently to get the bearing out.

note: use some caution here, if the bearing cage is trashed then you'll end up with all the BB's in the cage rolling out and hopefully onto your front deck. you can put the BB's back into the cage if you have been careful and used the rag to catch them.

if you need a new bearing cage they are ~$1.60 each directly from Minn Kota at 800-227-6433 and order part number 2266000. Local sources may be available as well, rumor is that The Hook carries stock

my dust cap and bearing are as dry as the desert, no wonder I had rust marks. but luckily the BB's stayed in the bearing cage.

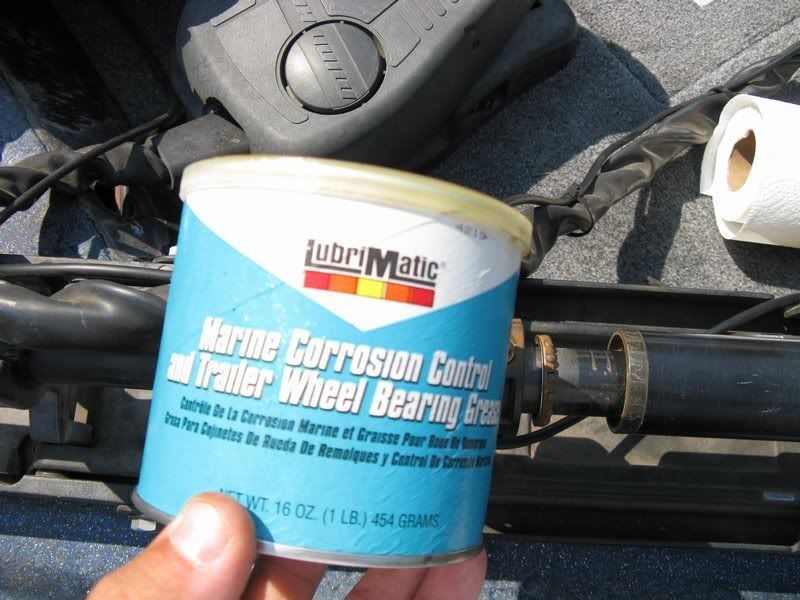

STEP 4: grease 'er up

I used a can of this bearing grease, took a dab of grease onto my finger and scraped it off on the bearing cup to get something up into the race. then applied it to the bearing cage and the dust cap

STEP 5: reassemble

rock the shaft gently while pushing the bearing cage with all the BB's installed back into the bearing cup/race, then repeat for the dust cap

slide the collar back in so that its snug onto the bottom of the dust cap -- you can't get it too tight, but you can leave it too loose so make sure it's up and snug (BABY!)

STEP 5: test

if possible drop the trolling motor while the boat is on the trailer then give it a go and make sure the shaft is moving smoothly and not bound up. go fish

Advertising

Advertising